Optimizing Energy Management in Heat Treatment: A Case Study with groov RIO Energy Monitoring Unit

Introduction

Energy management is one of the main strategic activities that can considerably impact the operational performance of industrial manufacturing companies. When companies engage in energy-intensive processes like vacuum aluminum brazing, it becomes essential to have a sound, reproducible way of determining energy usage. This article presents a comprehensive case study of how the groov RIO Energy Monitoring Unit (GRV-R7-I1VAPM-3) was utilized to transform energy monitoring, cost analysis, and preventive maintenance for a client in the heat treatment industry.

The Challenge

Methods like vacuum aluminum brazing are power intensive, and many subtle factors must be closely regulated to achieve good performance and high throughput. One of the major operations our heat treatment customer faced was energy consumption; energy loss was costly and impacted performance.

The following are three areas the client identified for improvement:

1. Monitoring Energy Usage: Energy consumption data must be nearly real-time and historical to gain more realistic insights into consumption profiles and problems. Without this information, it was hard to identify areas for optimization or measure the impact of any changes.

2. Calculating Running Costs: A more detailed separation of energy costs at the machine level was necessary to attain greater financial clarity. The system was expected to correlate energy consumption with respective operations to facilitate rational decision-making.

3. Identifying Issues: Energy trend analysis is the priori of predictive maintenance, which shows characteristics of a possible equipment failure. In such circumstances, early intervention prevents costly time loss and increases the useful life of crucial equipment.

Even though all of these needs could be identified effectively, the existing infrastructure at the client was inadequate to support these objectives. They did not have integration of SCADA with energy monitoring or the ability to get insights out of it. This lack of information allowed the client not to have a coherent picture of their energy consumption, which made it hard to introduce improvements to their operations or to be able to address new problems as they arose. To fill this gap, the client needed a high availability and secure solution that would conform to the current client architecture yet offer full energy data and analysis. This should translate into usable information to form the initial foundation for cost management, process improvement, and equipment reliability.

The Solution

The groov RIO Energy Monitoring Unit (GRV-R7-I1VAPM-3) was selected to be ideal for energy monitoring because of its larger range of features and versatility over the ability to input into existing systems. Formerly, it is a narrow-edge I/O device that can be operated without depending on PLC, PAC, or IPC. Critical aspects are Category III 3-phase AC power monitoring up to 600 V, which is very important in any industrial environment. It records 18 parameters in each phase, and the significant parameters include voltages, currents, and power factors by which energy and performance of the system can be monitored effectively.

It also provides multiple communication modes, such as MQTT/Sparkplug, OPC UA, and Modbus TCP, and can smoothly transfer data to other systems or cloud applications. This makes it easy to retrofit into existing building structures and allows the utilization of already developed physical structures. Configuring the channel is easy, achieved with the help of groov Manage software, which is browser-based to allow for easy management and control of the monitoring unit.

To provide the optimum safety and work output, OPTOEMU-ACT-1250-400 split-core current transformers were used. These CTs allow safe and nonintrusive energy metering sans any modifications to circuits that can disrupt service continuity while enhancing operational efficiency. In conclusion, the information relayed through the groov RIO Energy Monitoring Unit and the split-core current transformers provides a solid, scalable, contactless energy monitoring system for industrial plants.

Integration with Existing Systems

The groov RIO EMU was configured with the client’s own SCADA system SpecView to the full extent of how the client desired. This system will create an extra layer to monitor and analyze, which will help them manage energy better and cut operational costs. The integration of this system brought several key features:

- Real-Time Monitoring: Using groov RIO EMU, the operators can see how the facility consumes energy in real time using the trending SpecView screen. The real-time feedback provided to the operators also enables them to establish where there are anomalies and take corrective action quickly.

- Data Logging: The system recorded long-term energy data, which meant trends were kept. Such data is stored to help the client analyze his usage pattern at different periods. This was essential in making forecasts and making wise decisions.

- Custom Reporting: An enterprise Windows energy data analysis and representation application was designed. It lets the operators upload a CSV file with all the requisite information, including time, current, and net power. It was possible to set variable rate schedules for energy costs and make comprehensive reports of energy consumption by machines and periods of maximum energy usage.

Results and Benefits

The deployment of the groov RIO EMU brought several measurable benefits:

- Detailed Energy Insights: The system collected 64 energy-related metrics to provide a detailed perspective on energy utilization. It provided this depth of insight by letting operators know where energy was used most and letting them work out how they could reduce it.

- Cost Analysis: The energy costs have finally been revealed to the clients through customized reports. Cost patterns enable the client to recognize where cuts may be made and ways to reduce the amount paid for energy bills.

- Enhanced Predictive Maintenance: Investigation of consumption, especially during the high load period, allowed the system to determine problems before they became massive. This helps to eliminate frequent downtimes and cut down on failure incidences. It also helps to adopt a preventative measure that eliminates frequent downtimes.

- Improved Operational Efficiency: Investigation of consumption, especially during the high load period, allowed the system to determine problems before they became massive. This helps to eliminate frequent downtimes and cut down on failure incidences. It also helps to adopt a preventative measure that eliminates frequent downtimes.

- Significant Cost Savings: The optimized energy utilization helped the client reduce peak demand charges and overall energy costs. The client achieved significant cost savings through active energy consumption management and efficiency enhancement.

In summary, integrating the groov RIO EMU with the SpecView SCADA system gave the client valuable insights into energy usage, leading to better cost control, enhanced maintenance, and significant operational savings.

Graphical Insights

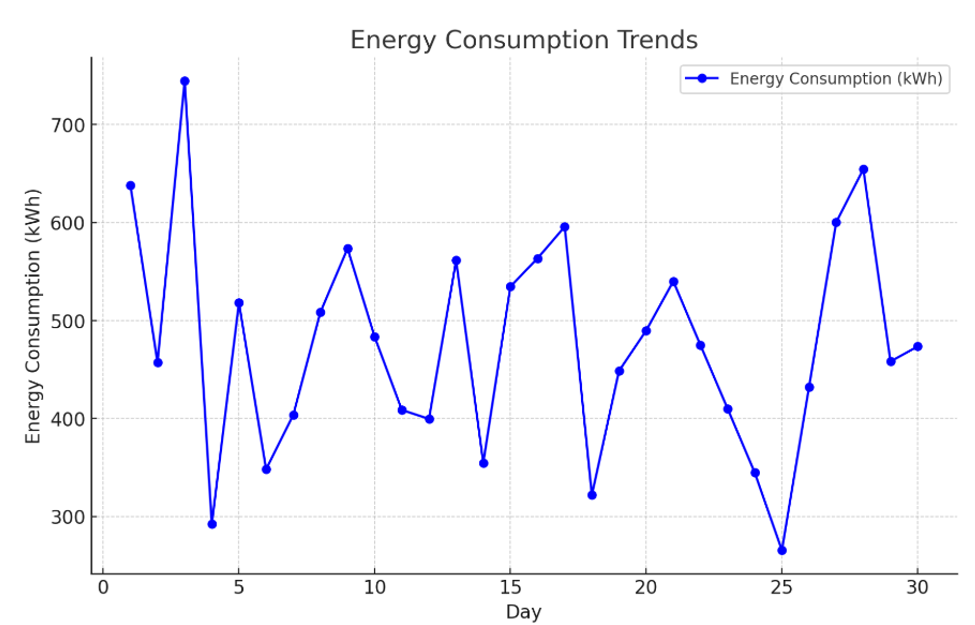

Figure 1: Energy Consumption Trends

This line graph illustrates daily energy usage over a month, highlighting peak periods and areas of high consumption.

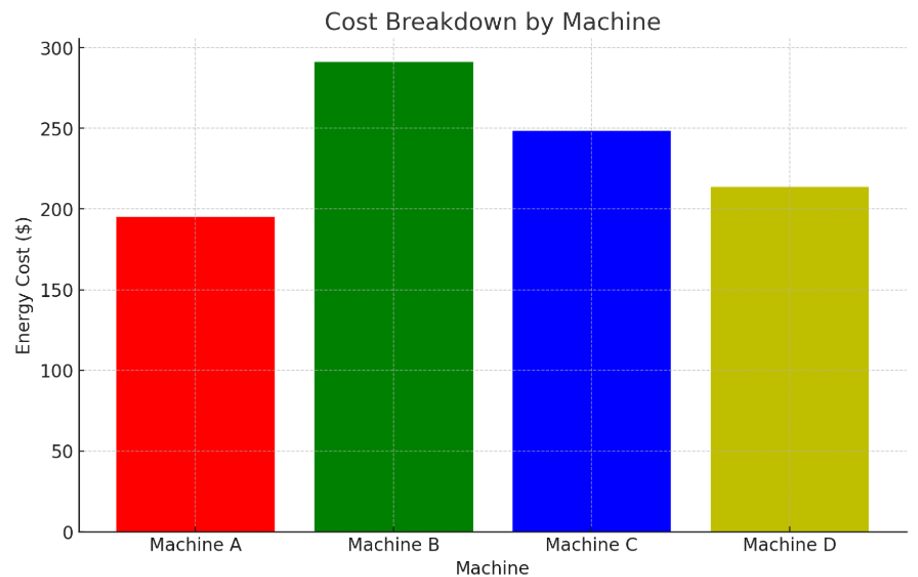

Figure 2: Cost Breakdown by Machine

A bar chart displays machine-specific energy costs, enabling precise cost allocation and optimization strategies.

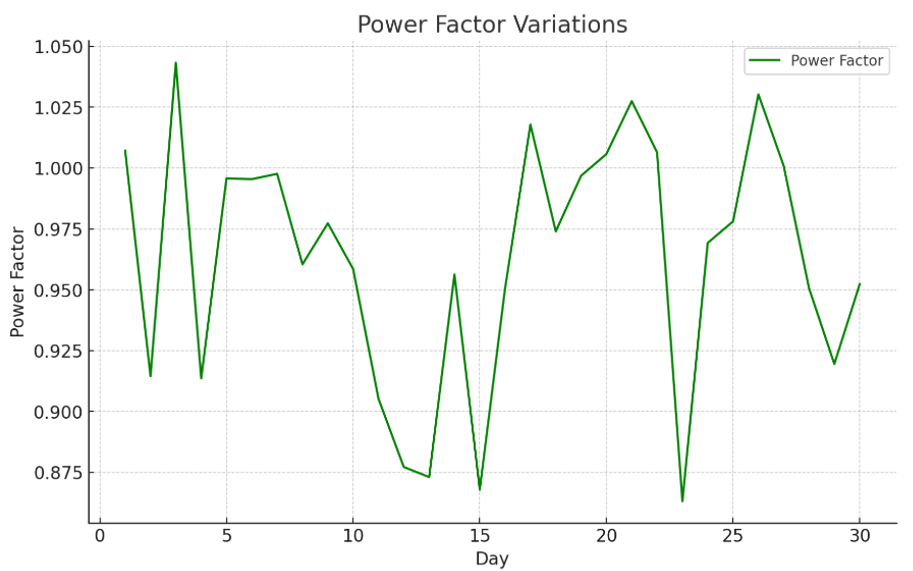

Figure 3: Power Factor Variations

A graph showing fluctuations in power factor over time, demonstrating opportunities for corrective actions.

Scalability and IIoT Capabilities

The groov RIO Energy Monitoring Unit (EMU) offers today’s most scalability and IIoT compatibility for today’s and future applications. It has MQTT/Sparkplug and Node-RED integration, so users can easily connect to cloud and analytics applications. This makes it easily flexible and can be integrated with other systems as the clients need them. Furthermore, adding value system components like TLS encryption and authentication ensures the safety of data stored in the system, its purity, and compliance with the norms.

Expanding Energy Monitoring Services

Building on the success of this project, we are expanding our energy monitoring services to offer a comprehensive solution to clients. Our service includes:

- Consultation: We offer specific assessments for energy monitoring within the system depending on the requirements and goals we have set with the client.

- System Integration: The groov RIO EMU is compatible with existing structures, enabling its deployment to occur without interfering with ongoing processes.

- Custom Software Development: Clients are offered data visualization, reporting, and cost analysis applications to track energy consumption and make necessary decisions.

- Ongoing Support: We also offer services that enable constant training and maintenance of the system to warrant constant service delivery and constant support to clients so that they can fully benefit from the system.

Thus, we may help companies and organizations minimize the efforts they spend on energy needs and outline their further development in the context of the advancing global industrial environment.

Conclusion

Groov RIO EMU acts as an energy management unit, and its integration into the client’s systems has brought positive changes in energy management. The integration of the SpecView SCADA system aimed to provide the client with features such as real-time monitoring and control, history logging, and reporting, allowing for better prospects in energy consumption and expenditures. The capability of gathering 64 energy metrics paved the way for monitoring and customization and in providing predictive maintenance that translates to operational improvement and less cost.